After a competitive selection process, APC Postal Logistics recently selected ID Parcel & Mail Solutions to design, build and install a new Packet Parcel Sorting System in their East Rutherford, NJ facility. APC is a leading consolidator and distributor of international parcels. They operate from three facilities across the U.S. to provide cross-border shipping and mailing services to over 200 countries worldwide.

By making the investment in a new Packet Parcel Sorting System APC will greatly improve their capacity to process more parcels and significantly reduce the cost of processing per piece. After a careful assessment of their current operations, it was clear that moving to automation would be a financially sound investment that would provide financial and customer service benefits for years to come.

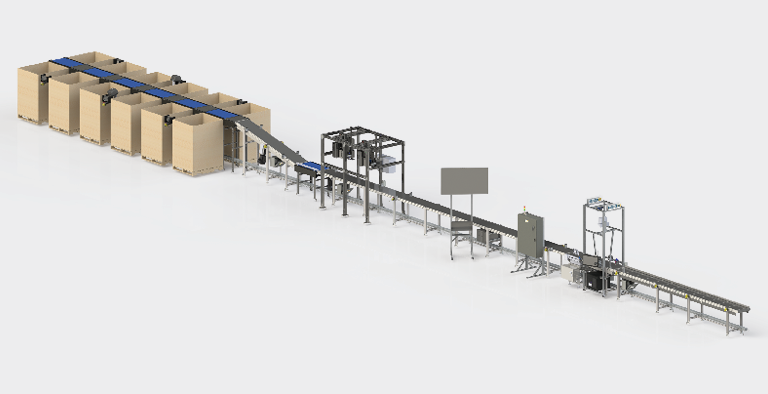

The Packet Parcel Sorting System includes automatic print and apply labelling and 13 sorting outlets. It will process mixed streams of small packets and parcels for cross-border distribution via APC’s delivery partners.

The system includes a two or three-person manual induction feeding area. It is designed to allow APC the ability to use one to three operators to feed compatible packets and parcels at speeds of an average of 2,600 pieces per hour assuming optimal size and weights, depending on length of the items.

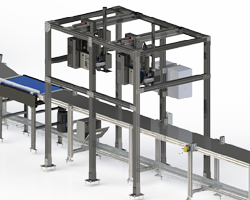

The included two automatic print and apply labelling applicator systems are a key feature and an APC requirement during the selection process that allows this system to operate with considerable efficiency. Automatic labelling uses the barcode scanning system to determine the location of the current package label and provides the coordinates to the PPSS. The PPSS then aligns one of the print and apply label applicators to the appropriate position so as to apply the new final mile delivery label on top of the existing label.

The solution includes integrating APC’s API into ID Parcel’s PPSS software and connecting ID Parcel’s Standard SQL IT interface to the APC IT system as well as the commissioning, acceptance testing, and training of the APC staff responsible for operating the system.

The PPSS system has all the components necessary to feed, barcode read, weigh, dimension, and print and apply labels on packets and parcels, and then sort the items to 13 sorting outlets with tracking of pieces to containers for manifesting of items to unique containers using ID Parcel & Mail Solutions’ sorting outlet control panels and two container label printers. It includes adaptation of the standard HMI User Interface software for integrating with the APC IT system for processing customer jobs and selecting various sort schemes, as well as data capture for each parcel and finalization process for APC to manifest with its partners.

The system comes with conveyors to transport packets and parcels through each processing stage. The design of the system is modular and allows APC to add more conveyors, optional manual labelling stations, and additional sorting outlets at a later date.

ID Parcel & Mail Solutions has worked closely with APC from the start of the project to assess their specific needs and design a system specifically to meet them. The engineering design phase is now complete and manufacturing is well underway. Installation is expected in late September.

Notifications