The PPSS system can be designed with various features and a range of options to most economically process and sort packages for distribution, ecommerce, postal, retail and warehouse applications. We’ll build your system to be the most cost effective by identifying the specific needs of your operation, and nothing else. This way we can configure or design a system that achieves your goals without the added cost of components or higher speeds that can’t be fully utilized and would add to the cost of the investment.

For demanding periods, the PPSS can accommodate up to four-persons feeding packages on the induction conveyor for maximum throughput However, on slower days, it can be operated with only one feeder. It is designed to easily ramp throughput up or down to meet shift or daily production requirements while minimizing labor expense. With both the option of automatic package labeling or manual labeling for irregulars or special labeling requirements, this same flexibility to deploy more or less operators allows operations to run the system with the labor resources required for that processing volume.

No automation solution works without reliable software and IT integration. The standard solution includes ID’s interfacing to a customer’s IT system via customer provided RestAPIs or other software integration methods. By allowing customers to maintain the business logic of their process, customers can quickly and cost effectively adapt those rules without incurring delays and additional fees. The PPSS provides the means of capturing data more efficiently and executing their business processes at much lower cost per piece.

The purchase of the system provides a comprehensive solution that includes the equipment, software, and the commissioning, acceptance testing, and training for the customer’s staff responsible to operate the system. For ongoing support, ID Parcel & Mail Solutions provides various levels of service and support to keep the PPSS running reliably over many years.

It’s all upside with the PPSS. If you’re experiencing increasing labor expense and challenged finding quality and reliable staffing, the PPSS will improve your operation in a number of ways. Here are a few...

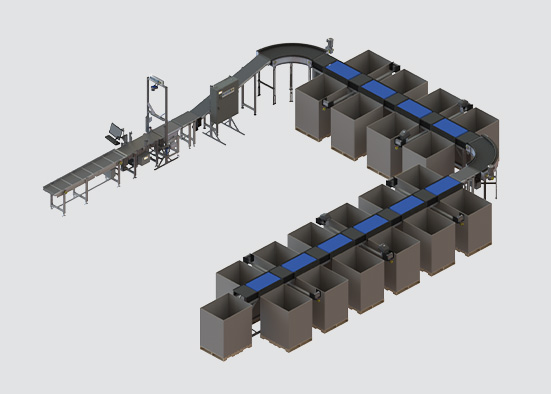

The PPSS is packed with standard features that will help make your operation more efficient right out of the gate. Additional features can be added when appropriate to the budget and requirements. Our team will help assess your operational requirements to ensure that your system is designed only with features that are necessary, and have the ability to impact your bottom line.

Some of The Key Features of The PPSS...