Each year our Client, a global eyewear conglomerate, is confronted with a short, but significant peak sales season. Just before Black Friday, and for approximately 10 days following, they receive a large spike in sales. Processing orders from their U.S. facility has been a challenge in previous years during this time. Although they have automated sorting systems in place to handle regular season demand, they were forced to manually sort the additional orders during the peak, as the volume was heavier than the available capacity of their large shipping sorter. This process was costly and susceptible to human sorting errors and made it very difficult to track package shipment to carriers. They needed a better way.

The Client needed a relatively small, supplemental parcel sorting system for their busy time of the year. ID Parcel & Mail Solutions was a comfortable fit for this type of project with the flexibility to provide smaller, high-quality systems at an affordable price point.

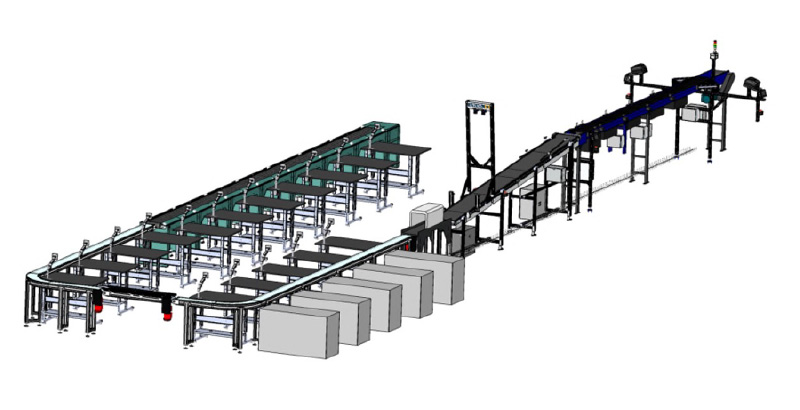

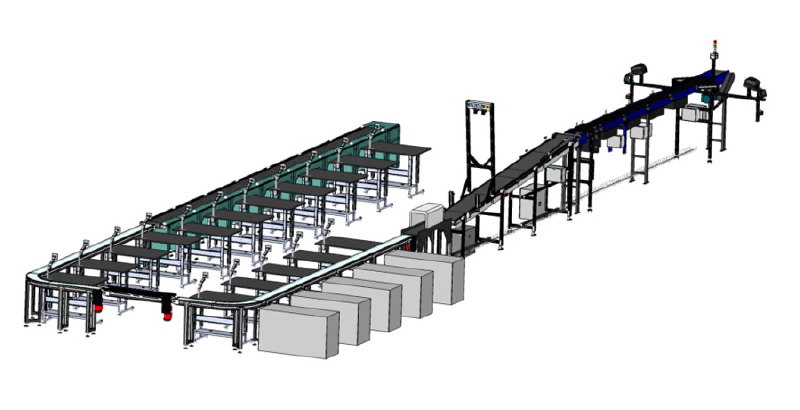

In 2021, they placed an order with ID Parcel & Mail Solutions for a Packet Parcel Sorting System (PPSS) for delivery in less than two months. Because the order had to be delivered so quickly, the initial design was a small PPSS made up of both new, sales demonstration, and remanufactured components and subsystems. It was configured to fit in the available area of 81 feet x 21 feet and support sorting at throughputs of 2,000 to 3,000 pieces per hour. It allowed space for 12 to 14 workstations, provided by the Client, to be placed on either side of the induction conveyor for parcel feeding after packing. The system read the top applied package label tracking barcode, updated the Client IT system, and confirmed the sortation with package to container tracking and container label printing

After a successful initial peak season with the new parcel sorting system, they requested additional system upgrades for an even more productive system for the 2022 season. These included an additional diverting assembly, new conveyors and reconfiguration to allow for a new U-Shaped Induction and integration with a RFID system supplied by the Client in line between the extended Induction conveyors and the sorting system.

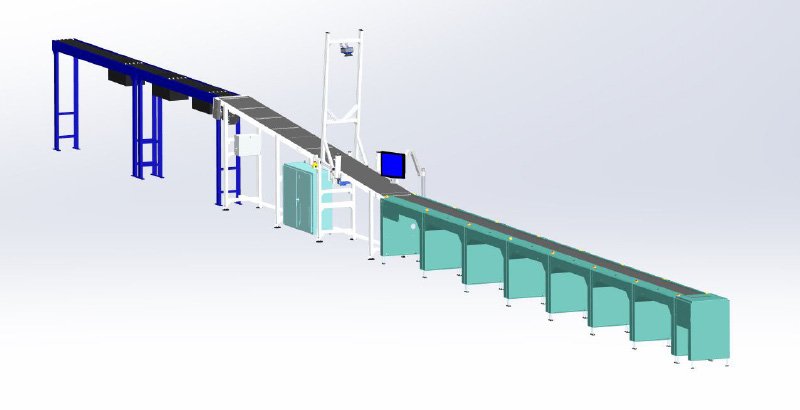

In an effort to configure the new components of the system to fit the existing facility space the Client had made available for the initial system, ID Parcel & Mail Solutions designed and fabricated a new U-Shaped Induction Conveyor system and moved the current Induction Conveyor to the new part of a U-Shape and integrated the new induction conveyor and a Rielec RFID Compaq Tunnel into the expanded 8 Outlet PPSS system already installed. This new design consists of a 4-segment Induction Conveyor system with a Lift Gate Conveyor at the center of the U for emergency egress when necessary. The new conveyors use a rugged but lower-cost plastic segmented belt that allows the conveyor to turn 90 degrees without needing another motorized conveyor, saving significant costs. The final design of the Induction system allowed the Client to place 27 order packing workstations alongside the conveyor to maximize the overall system throughput. At the end of the Induction system, ID designed and installed a metering subsystem to ensure only one piece was released into the RFID Tunnel at a time and when the RFID Tunnel is ready. This ensures that each package has the optimal presentation to the RFID reading devices so it is registered. This integration with the RFID Tunnel created additional savings and quality control to ensure the correct item was shipping to the correct customer. If the RFID read does not match the customer order, the PPSS will reject the package so it is not shipped and can be examined and corrected.

Finally, as the gaylord containers are filled with outbound packages by carrier, operators use the innovative color touch screen sorter outlet control panels to close containers and update the PPSS when a new empty container is in place. This control provides package tracking to the container, and with the software integration with the Client’s IT system, provides a confirmed shipment transaction as the gaylord is closed and available for the shipping partners’ pickup.

The resulting configuration and parcel sorting equipment has proven to be very effective for the Client, and will continue to help streamline the fulfillment of orders for years to come during their busy season.

"Our parcel processing overflow during peak season was subjecting the organization to heavy operating costs, additional labor requirements, and negative impacts on customer service as manual sorting could result in delays and errors that were affecting customer satisfaction. ID Parcel & Mail Solutions was a perfect fit to design build, and integrate a low-cost parcel sorting system for our requirements. Their organization is flexible enough to quickly deliver critical systems, yet they provide the level of technical and professional acumen typically found at a much larger organization, while also delivering a high level of support"

- R.M., Director of Engineering at global eyewear conglomerate