When Sandd, now part of PostNL, was in need of an OCR sorting solution it turned to ID Mail Systems, a mail and parcel sorting systems manufacturer, which had previously supplied Sandd with its 120-bin Dispatcher.

A private postal company in the Netherlands, Sandd processes nearly 700 million items per year, delivering a variety of mail types from bulk mail, such as invoices and bank statements, to magazines and direct mail. With 27 properties and a delivery staff of over 14,000, the company can provide 100% of the national coverage of addresses to its customers. Sandd is unique to the Netherlands because it not only saves its customers up to 25% on rates, but each mail piece is applied with a Sandd code that defines the mail piece routing and date to be delivered.

Prior to purchasing the OCR stations, Sandd had been using its own hand coding system for non-machinable mail, and staff had to key in the delivery address for every piece. The company was searching for a method of handling these items faster, while also updating its software to meet new customer requirements. Already having a few years of experience with the ID Mail Dispatcher, and knowing ID Mail provides hand-coding stations as well, Sandd reached out to the company for an OCR solution. Victor Jacobs, technician coordinator for Sandd, explains, “Other suppliers had similar systems in performance, but we would have ended up with two separate systems. ID Mail was able to provide a software package where both systems were combined to create and close customer orders, ready to be uploaded in our company IT system.”

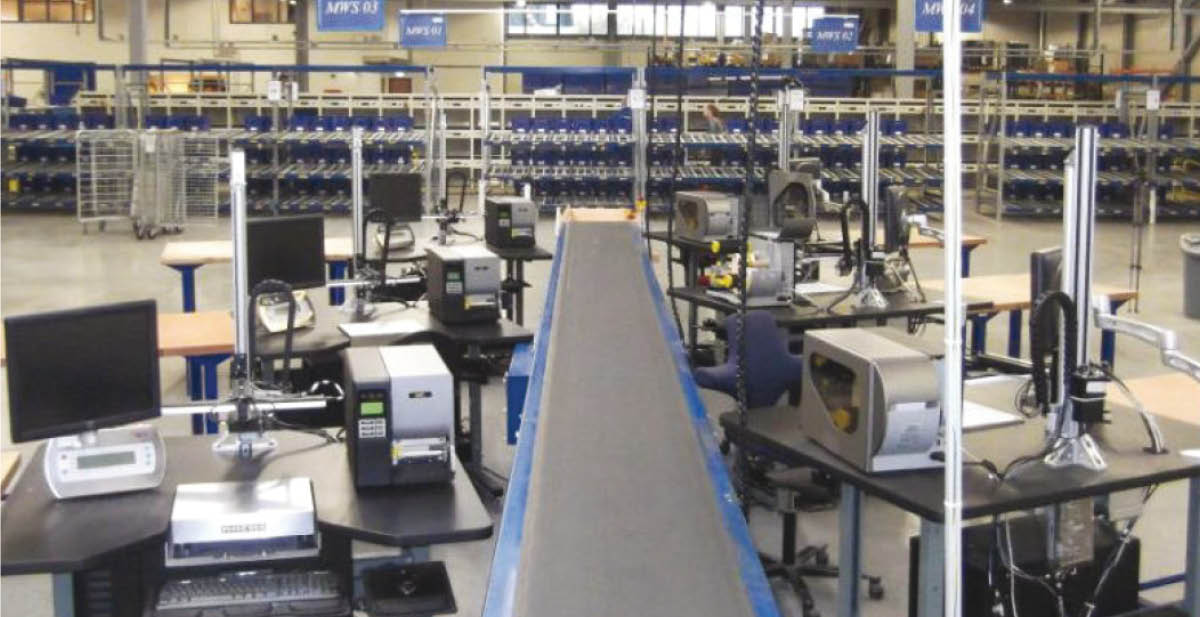

ID Mail provided Sandd with new MMW (manual mail workstations) systems for processing small batch and non-machinable mail with the identical coding logic and database that is presently being used on its Dispatcher. ID Mail was able to utilise the SQL data interface between the Sandd IT system and the current ID Mail Dispatcher, thereby providing identical mailpiece data and

eliminating a significant effort and risk to achieve a seamless integration. Sandd’s goals for the project were to process mail faster and assign each piece the complete Sandd code. Also, with a growing number of customers, it needed the new system to be fully operational within a couple of months. After a short training session, the company’s operators had no trouble working with the MMW systems.

Previously, the operators were running around 200 pieces per hour, but with the installation of ID Mail’s OCR workstations, that has increased by 100-150%. This was achievable because of the MMW’s ability to utilise the ID Mail World.ware OCR coding software and Sandd’s logic and printing requirements developed for the Dispatcher. The increase in efficiency was also achieved by the integrated data capture for billing and operational measurements through

the ID Mail Interface system, including accurate and actual mailpiece weight for each item processed.

The ergonomically designed workstations also improve operator productivity and comfort as well as stability for weighing accuracy. Each workstation was installed to a fixed height to suit each operator. Having worked on and observed the workstations for over six months, Jacobs appreciates

“the way the system can easily be adjusted to our unique Sandd process, and the possibility to code every mail piece with or, if necessary, without the OCR camera”. ID Mail’s OCR workstations are usable for letters, flats and small parcels, and more importantly, are affordable for Sandd’s mail

volumes, making it the complete package.