When considering franking machines the tendency is to think of tabletop units with letters or large envelopes fed to it by dedicated operators. At the conclusion of processing you are left with a pile of items with an indicia or similar imprint. In keeping with that logic, Post Danmark envisioned and then enacted that system when it first began franking items for its business customers. And for a while it worked well.

When labor and lease expenses were analyzed, it became clear that the roomful of franking machines with dedicated operators wasn’t the ultimate solution. With an eye towards improving its margins, Post Danmark began looking for a more cost-effective solution to support its business customers.

When the search began, several factors were specified by Post Danmark as ‘givens’ for the new franking system:

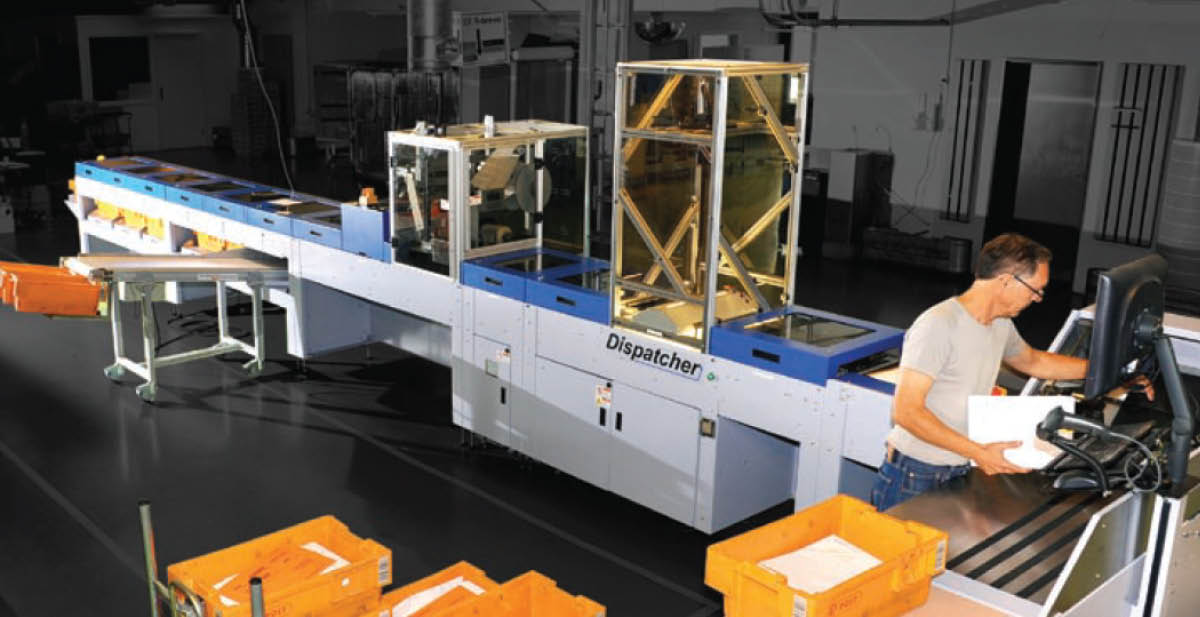

Although not a franking machine per se, the Dispatcher performs all the essential franking machine functions including item feeding, weigh-in-motion and indicia printing. In addition, it can also OCR read addresses, delineate between different items by size, print further lines of information and sort items according to pre-assigned schemes. Knowing that no single system could process the wide range of thicknesses, shapes and weights of Post Danmark’s customers, ID Mail also proposed a small number of touch screen Manual Mail Workstations, or MMWs.

Completing its offering was software to provide two-way communication between Post Danmark’s existing SAP system and each processing node as well as the operating software for each Dispatcher and manual station. Each node would be linked to ID Mail’s central on-site server, which in turn would be linked to the SAP database.

“We knew we couldn’t be a ‘me too’ system, because we simply don’t play in the traditional franking machine arena,” said Jerry Fenerty, ID Mail’s president and CEO. “That allowed us to propose a somewhat radical approach that married well with Post Danmark’s needs.”

Post Danmark was intrigued by the proposed system, especially the flexibility the new Dispatcher MX would bring to its business-mail operation. Not only could the proposed ID Mail solution process many more items per hour across a wider range of sizes, including its bulky and thick items, but it could do it in a more streamlined fashion. The interconnectivity of the ID Mail processing stations, their ability to seamlessly switch to a different customer and the vendor’s willingness to adapt to the existing data structures, convinced Post Danmark that ID Mail had the winning solution.

Michael Jack Truelsen, from Post Danmark Franking Services, stated “ID Mail was selected as the supplier of this multi-system solution because they demonstrated the aptitude, experience, and flexibility to meet the critical requirements of Post Danmark. The Dispatcher mail processing system is unique in its affordability and superb range of features allowing it to process a very wide range of mail items with high levels of productivity.”

Processing the mail It all begins with the two-way communication between SAP and ID Mail’s central server. At prescribed intervals the SAP server downloads new customer information and changes to existing customers to the ID Mail server. In turn the server makes this same information available to each of ID Mail’s systems, enabling customer mail to be processed immediately.

On arrival at either the MX or a manual station, the appropriate customer information is automatically loaded by reading an ID tag. The barcoded information printed on each customer ID tag tells the system which customer is about to be processed, so the appropriate print layout, indicia and logo can be loaded from ID Mail’s proprietary WORLD.ware file.

Used around the world in a variety of applications because of its flexibility, WORLD.ware is used by each node as its own on-board decision engine. For example if the MX or MMW is processing mail for Customer X, WORLD.ware decides the rate to charge and the indicia to apply based on the item’s thickness, weight and destination. The coupling of the barcoded ID tags and WORLD.ware effectively streamlines the setup of the MX and MMW, eliminating the need to manually select a customer, job and print layout, and creating substantially more mail-processing time.

Following set-up of the MX, the items to be franked are placed on its automated in-feed section if they are either a letter or large envelope. But what about the bulky and over-thick items encountered throughout the day, traditionally considered non-machineable mail? Though these items could be processed on the MMW stations, ID Mail brought yet another innovation to the table – its manual in-feed station.

This allowed a much greater range of mail to be processed, at speeds in excess of 1,500 to 2,500 per hour. When processing such items the operator simply turns from his normal position and places items individually on a new manual in-feed belt downstream from the automated feeder. A series of alignment rollers move the items into position against a registration plate, so little care by the operator is needed when placing them on the belt, allowing the operator to concentrate on speed. Completing the picture for the MX transport is its updated 30.5cm field-of-view greyscale camera mounted well above the transport belt. Such an arrangement enables over-thick items to be successfully imaged without the need to focus.

When processing thousands of items per day, ergonomics is a key issue. Post Danmark was no different and this was emphasized from the outset by the customer. ID Mail knew it had to change several aspects of its bin subsystems to comply. The customers’ tubs were too large to fit within either of the vendor’s existing bin types, so ergonomic changes were included in the redesign.

To help control costs and stay within budget, previous control systems from the TL3 stacked bins were used, resulting in a single-level three-bin subsystem, the SL3. While each bin within the SL3 was made longer to accommodate the Post Danmark tubs, that was just the beginning. The bins were also elevated several centimeters to make them easier to move. In keeping with the noise dictates for European processing facilities, the sound output from the bins was considerably reduced, enabling normal conversation while standing beside them during operation.

Although the majority of items are processed on the Dispatcher MX, the touch-screen MMW stations were an invaluable addition to the overall processing efficiency of the install. With an experienced Post Danmark operator, the PC-based MMW is typically achieving throughputs of 600 to 700 items an hour, which is substantial given that most of the items are either boxes or packets and heavier than a normal envelope. “We knew the Dispatcher couldn’t process some of the more parcel-like items, so our overall solution included the MMW from the outset,” offered Fenerty.

Other processing innovations

Variable franking modes: In addition to billing clients through SAP, Post Danmark also needed to frank mail on which postage had been prepaid or for a one-time client. This feature was implemented so that different payment methods could be accommodated.

Intelligent mail barcodes: Although not used by Post Danmark today, the MX and MMW systems are both capable of reading an intelligent mail barcode. When demand from its customer base builds, Post Danmark can use the barcode’s imbedded information to further improve processing of small customer batches of mail by automatically reading the billing account information from the mailpiece.

Security levels: In an operational environment where associates have varying skill sets, it is sometimes advisable to include different security levels so that software features are surfaced to some but not all associates. Password protected, the MX includes this feature at several levels, with technicians having a greater number of diagnostic features than operators. Other benefits: Post Danmark recognised that the Dispatcher’s intelligent features and capabilities could be harnessed for more than just franking, and requested ID Mail to provide a Business Reply Mail and Revenue Protection solution using the same hardware. ID Mail provided an easy and familiar user interface for both these modes that allows Post Danmark to gain greater ROI on their investment by automating Business Reply Mail charge-backs and auditing permit mailings for revenue protection.

When this news was created Post Danmark had installed eight Dispatcher MX systems across its three business mail processing facilities in Copenhagen, Fredericia and Aarhus. The overall success of ID Mail’s solution is testament to ingenuity and adaptability. Its flagship product, the Dispatcher mixed-mail transport, was reborn as the Dispatcher MX, not by starting over but by combining it with new and existing technologies. With state-of-the-art software and greatly enhanced hardware, ID Mail is well positioned for the challenges of postal authority processing around the world.