ID Parcel & Mail Solutions has designed and built automated parcel and mail sorting systems for leading Parcel & Mail Processing Companies from across the country and around the world. Following are a few of the reasons companies have relied on our experience to deliver cost effective, flexible automation solutions.

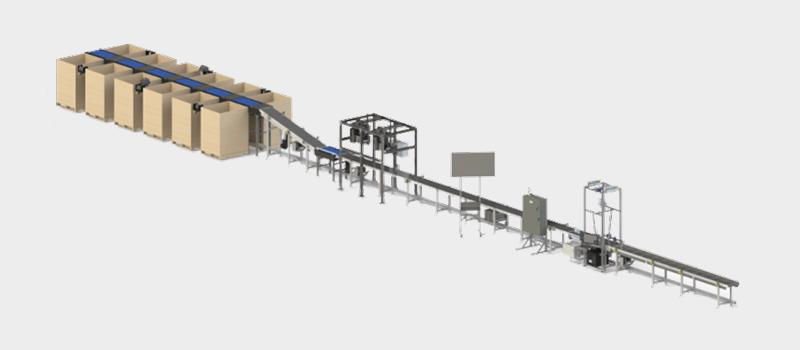

APC Postal Logistics, a leading consolidator and distributor of international parcels, recently selected ID Parcel & Mail Solutions to design, build and install a new Packet Parcel Sorting System (PPSS). The new system greatly improved their capacity to process more parcels and significantly reduces the cost of processing per piece. Parcel sorting efficiency has also been improved with the inclusion of two automatic print and apply labelling applicator systems. The labelers were a key feature and an APC requirement during the selection process.

ePost Global (“ePost”), a premier international mail and parcel shipping solutions provider, called on ID Parcel & Mail Solutions to design and build four Packet Parcel Sorting Systems (PPSS) for its processing locations across the country. With different facility layouts and needs, ID tailored each system for each site. One of the installs employed a phased approach. In phase one, ePost was looking for the immediate ability to take advantage of the speed and efficiency of automated packet and parcel scanning, weighing, dimensioning, and labeling. Phase two of the system added the sorting and piece to container tracking capabilities. ID Parcel & Mail Solutions worked to minimize the disruption on ePost’s processing operations. This was accomplished, in part, by scheduling a large amount of the installation over the weekend in a live processing operation which minimized system downtime.

PostNord A/S (Post Danmark), the postal service provider to senders and recipients in Denmark, has been using several ID Parcel and Mail Solutions’ Dispatcher MX Mixed Mail Sorting Systems and MMW Systems for providing postal franking and Business Reply Mail processing for over 15 years! However, hardware and software elements of these systems became obsolete and difficult to support. ID Parcel & Mail Solutions provided new technology to replace the obsolete components to keeps the systems core technology current and functional. This included traveling to Denmark to upgrade the systems’ computers, cameras, software, printers, and other components to ensure PostNord can continue to operate these machines with state-of-the-art technology for years to come.

ID Parcel & Mail Solutions designed and built a Packet Parcel Sorting System (PPSS) for Wizmo, a leading Canadian B2C delivery solutions provider for large volume shippers. The system was specially designed with a u-shape layout to accommodate material flow within a tight warehouse configuration. The system provides automatic weighing, dimensioning, scanning, and sorting for the processing of mixed streams of small packets and parcels. It also includes IT integration for piece to container manifesting. These features provide a range of benefits that include up to 4-5x increase throughput per man hour compared to their previous manual processing methods.